News

News News Press Software

New app: Fault images simplify repair and documentation

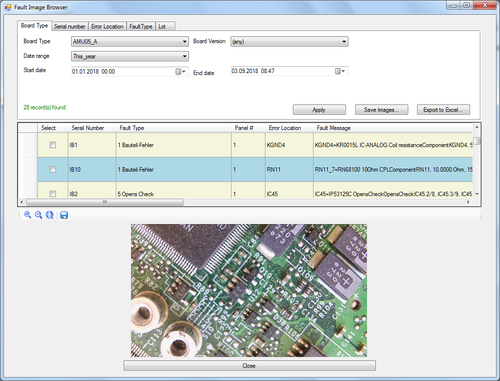

A picture says more than 1,000 words. This was the sentence that the developers from the test system manufacturer Digitaltest had in mind when they programmed the Fault Image Browser. Here, a camera connected via the PC takes pictures of found failures. Photos of assembly faults, defective components or successful repairs, for example, can be taken, saved and evaluated. This app is part of the Paperless Repair Software QMAN from Digitaltest. It helps all common test systems to repair faster and to observe and evaluate the manufacturing process.

This is how the new Fault Image Browser works: The user calls up the fault ticket, takes a photo with a webcam and it is automatically saved in the QMAN database. Any number of images - including descriptions - can be assigned to a fault. The fault images can be called up at any time and can be selected and saved individually, in several or all of them, as well as exported as Excel spreadsheets. The user can limit the fault images in advance, for example by period, board type, serial number, fault location or fault type.

Early identification of serial faults

The Fault Image Browser enables the analysis of error images, so that problems can be quickly identified, and production can be optimised accordingly. The photos show whether, for example, errors occur during solder paste application, assembly or soldering, whether the raw circuit board may have defects or whether components have already been delivered with defects. If a serial defect is known, the corresponding photo can be deposited at the visual inspection station to ensure special attention.

Transparency and repair support

For customer complaints, service cases or field returns, the fault image database can provide transparency and simplified communication. This QMAN function can help customers to better visualize recognized defects, especially in electronic manufacturing services (EMS). Of course, a fault image also supports repairs and makes it possible to record the successful repair photographically.

Document quality improvement

If production processes have been changed in order to avoid errors, the success can be optimally documented with the Fault Image Browser. The fault images allow a clear batch comparison and can give hints for further improvements. The Excel export of fault images is particularly suitable for this purpose. This file can be edited, forwarded as information or archived for documentation purposes.