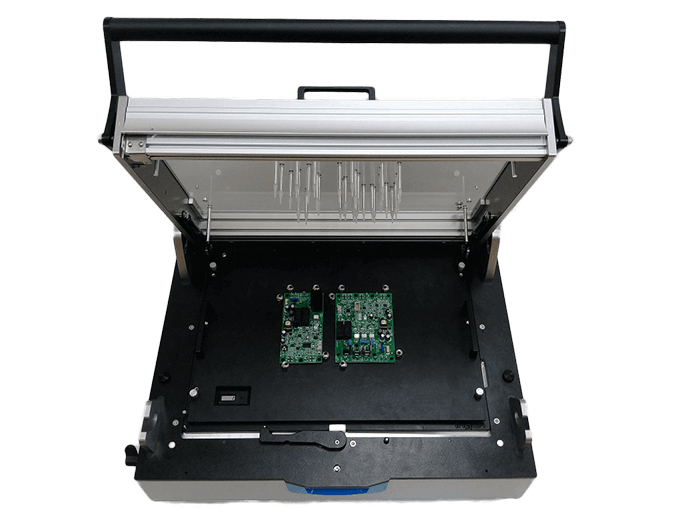

In-Circuit Test System with Vacuum Interface

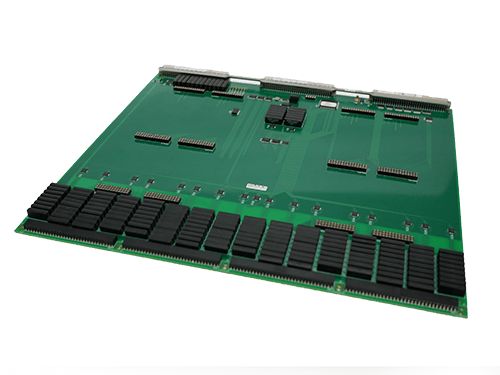

The Sigma is multifunctional. It offers a lot of space for modules and functions, with a small footprint.

- Up to 3,456 pins

- Small footprint (<1m²)

- Vacuum or cable interface available

- Short measuring paths

- Real parallell test with Lambda edition

Downloads

- Product Flyer Sigma MTS 300 (A4 Format)

- Product Flyer Sigma MTS 300 (Lettersize Format)

- Test System Overview

- Test Strategy Flyer

- Case Study MELECS EWS - Efficient and user-friendly

- Case Study Diehl Controls - Better through international support

- Case Study Continental AG - High test coverage, easy to use

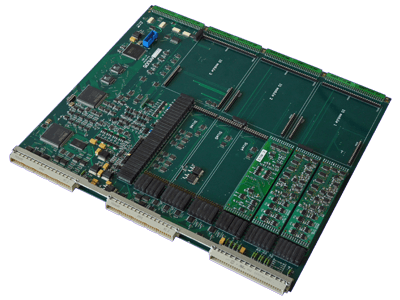

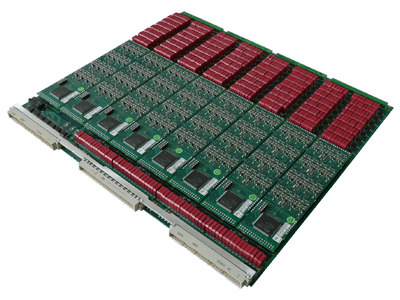

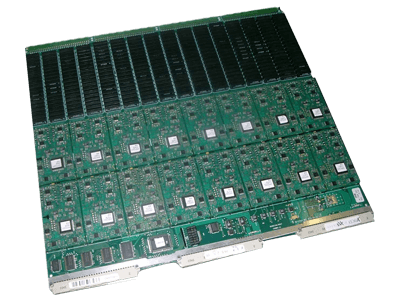

Our Sigma MTS 300 has been designed for high throughput capability and with up to 1000 measurements per second it is one of the fastest in-circuit testers on the market. The test system can check your circuit boards with up to 3456 analog, 1664 hybrid or a combination of both test points. The Sigma puts flexibility, high fault coverage and simple programming at the fore.

You can use the modular test system for analog and digital in-circuit testing, vectorless testing, functional test, boundary scan and memory programming. Thanks to the non-multiplexed pin architecture it is also possible to use fixtures and test programs from other test systems.

Fixture alignment aid

With the optional fixture alignment aid, the fixture can be easily positioned at the interface and placed using a life mechanism. The fixture runs on two rails – like a drawer – and is correctly positioned using positive stops as well as standard jaws.

The fixture alignment aid can be retrofitted on existing systems and has a load capacity of up to 400 N. The standard version is designed for a fixture size of up to 600 x 600 mm – but of course we also offer custom solutions on request.

In-Circuit Test

Functional test

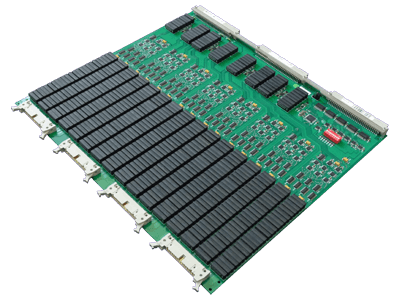

Lambda edition: real parallel testing as the solution

Would you like to test multiple boards in parallel and save time? We have the solution: real parallel testing with the Lambda edition. With this technology you can test two or more assemblies at the same time, thereby optimizing the cycle times and shortening the test time or performing the tests using the shortest path. An ICT or functional test is performed by two or more independent test heads, reducing the test time by the corresponding factor. This applies to multi-panels as well as for multiple independent single test objects.

The Lambda edition thus reduces the test time for two objects for example by 50 percent, or 75 percent for four, and so on.

Advantages of parallel testing

- Optimizes cycle times

- Small, economical test heads

- Powerful, flexible software environment

- Assemblies can be tested without additional effort

- Low hardware costs

- Takes up less space

Boundary Scan ICT

With our boundary scan upgrade for In-Circuit Tests (ICT) you can get the best of both testing methods worlds and achieve an optimal test strategy with maximum test coverage and reduced overall costs.

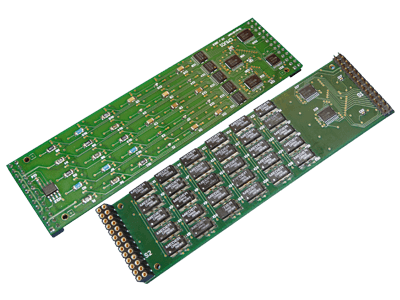

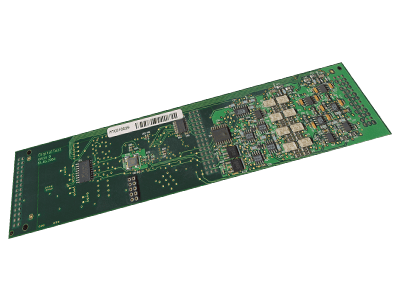

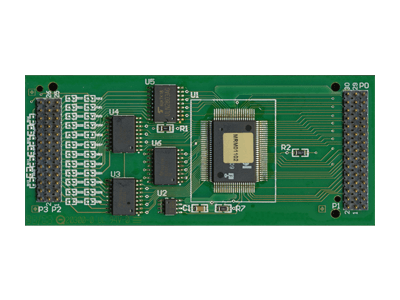

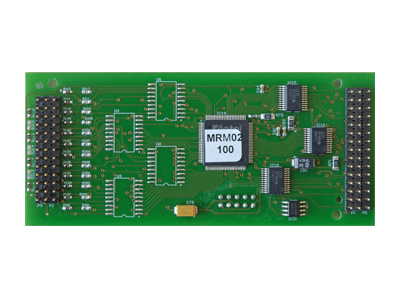

CAN-/LIN-Modules

The CAN-/LIN modules are standard interfaces for communication with the test object.

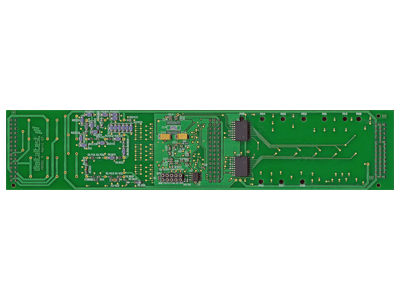

Programmer Modules

With the Programmer Modules you can make specific selections for onboard flash programming. Here we integrate for example programmers from Ertec, SMH, ProMik or Algocraft.

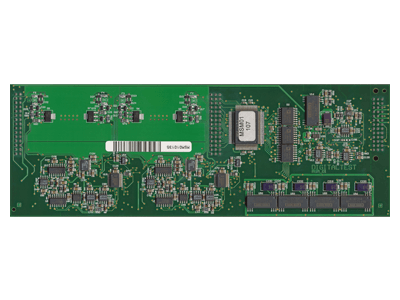

IEEE-, RS232-, USB-Modules

These functional modules have standardized PC interfaces for communicating with additional function test modules.