Flying Probe Test System

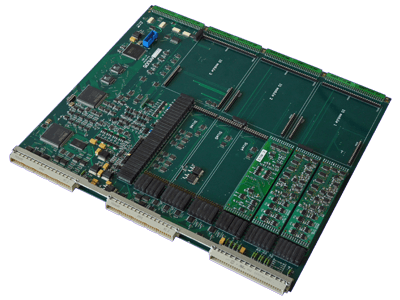

The Condor can combine different test methods and can therefore be used universally for all test strategies.

- 4-head flying probe system

- Universally applicable for all test methods

- Frontloader (manual loading), also available in-line

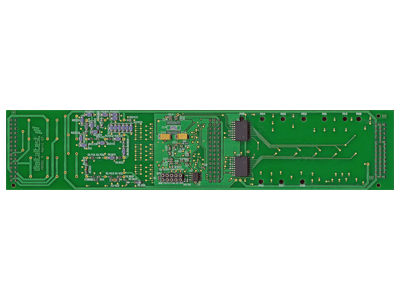

- Printed circuit boards without test points

- Optional fixture with up to 1,012 fix pins

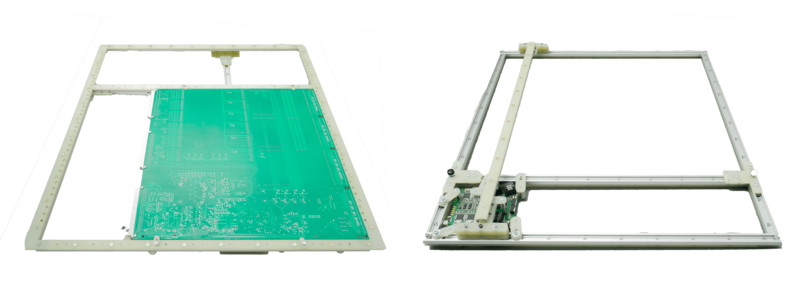

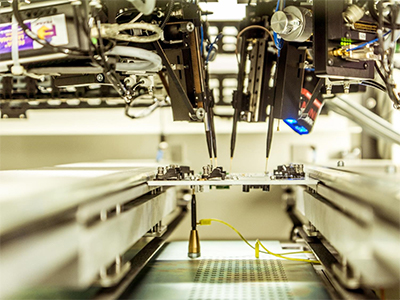

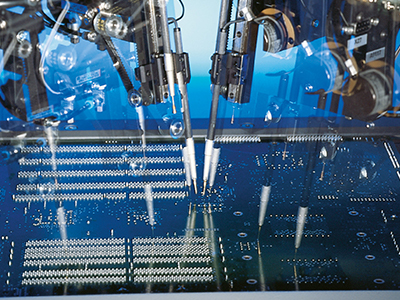

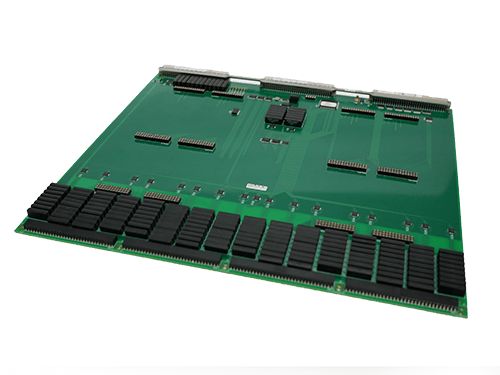

Our Flying Probe Tester Condor MTS 505 can combine different test methods and can therefore be used universally for all test strategies. Due to the four movable test heads, it offers a high adaptation depth and test coverage. The optional use of fix test pins at the bottom of the DUT additionally reduces the test time and increases the test coverage.

It is available inline with a conveyor belt or as a front loader for easy manual loading.

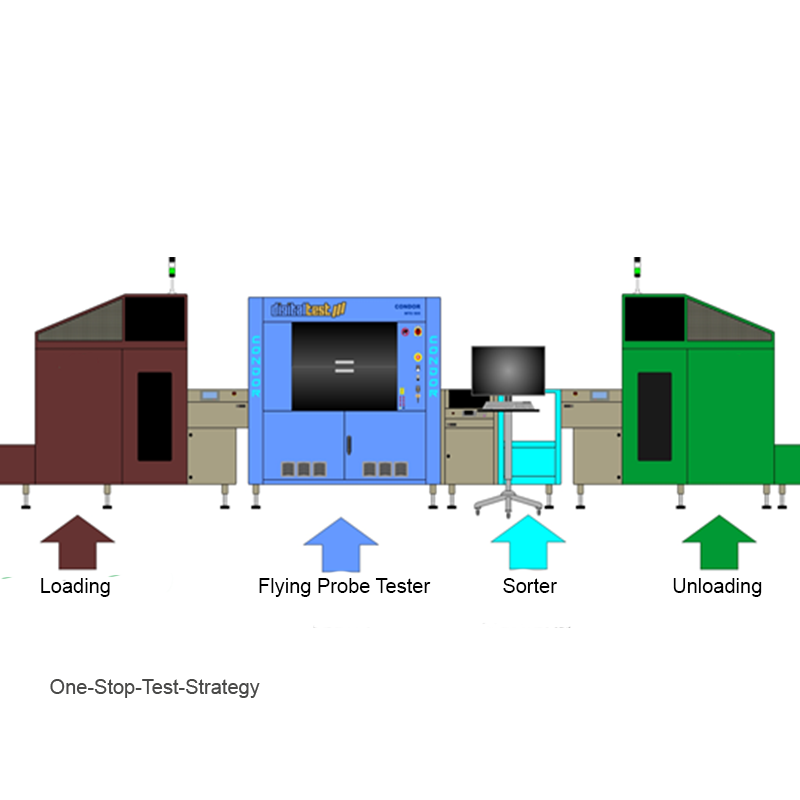

One-Stop-Test-Strategy

Create your own individual one-stop strategy from the various test methods, such as analog, digital and functional in-circuit test as well as boundary-scan, flash programming and LED test. This means that with this one production stop all test methods can be realized on a Condor Flying Prober. This saves costs for equipment, personnel and workspace.

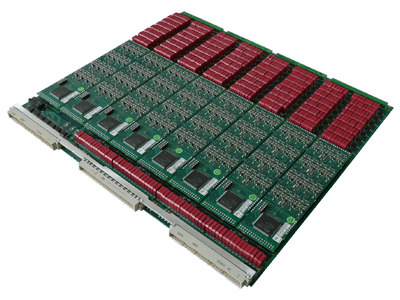

Double sided contacting

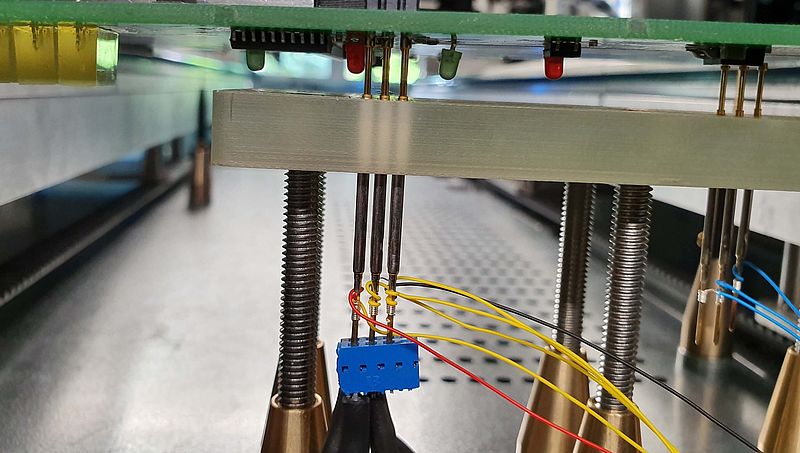

The Condor Flying Probe has four movable probe heads that contact from the top of the board. Each head is equipped with a measuring instrument module which contributes to the amplification of the measurement and guarantees a high stability and accuracy. From the bottom side it is possible to use magnetic fix-pins or to contact with a simple, inexpensive fixture. This saves test time and complex functional tests, and programming is also easy. With the help of these fixtures and our conveyor table, which is adjustable to the millimeter, we can make different tests by contacting different components in two levels. These are so-called dual-level fixtures, which we produce by ourselves.

Single-Axis concept versus Multi-Axis Flatbed

In almost all flying probes, the test heads move on rails on single axis. This means that if there are several heads in one system, they are extremely restricted. To reach a certain position, all heads must be pulled back to make room for one head so that it can move to that position. With the Condor Flying Probe there are no restrictions on the movement of the test heads because ours really “fly” on a flatbed of multi-axis principle linear motion. Each head can fly autonomously to its target position, which must be tested. The heads move on an air cushions smoothly and this guarantees an almost maintenance-free system.

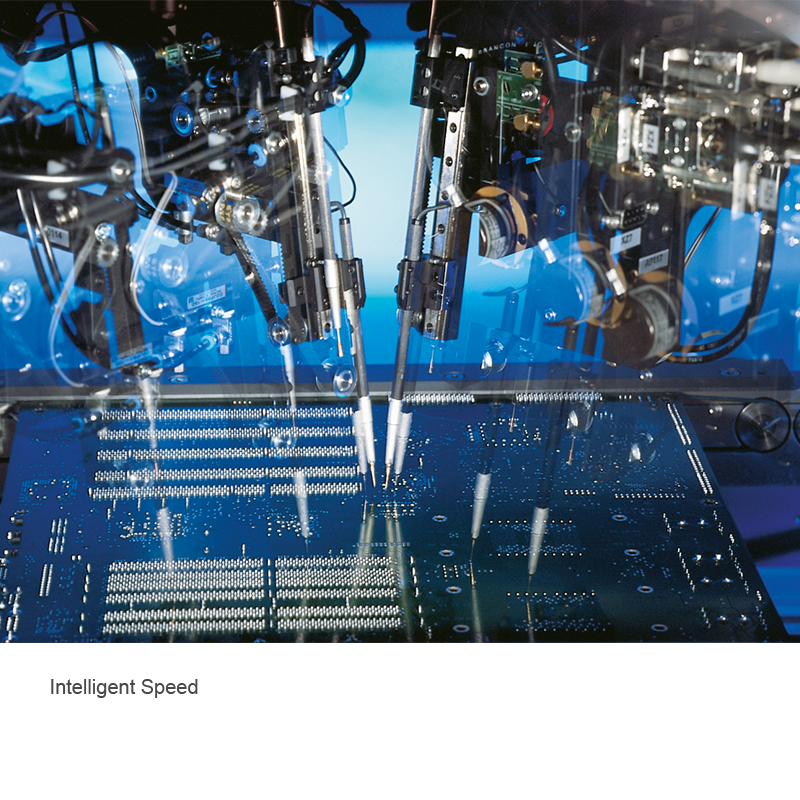

Intelligent Speed

We have a so-called "conveyer" that uses intelligent algorithms and the measurement functions of the hardware to calculate the optimal test method. You can think of the conveyer as a GPS for the test, it calculates the fastest test route for the different test positions. So you can take several measurements at one test position; the number always depends on the position of the components in the circuit. In addition, this number can be increased if magnetic fix pins are applied from the bottom, which again drastically reduces the total test time. The Condor achieves highest coverage with minimum programming effort and calculations, as well as reaching any point on the board with the shortest distance travel.

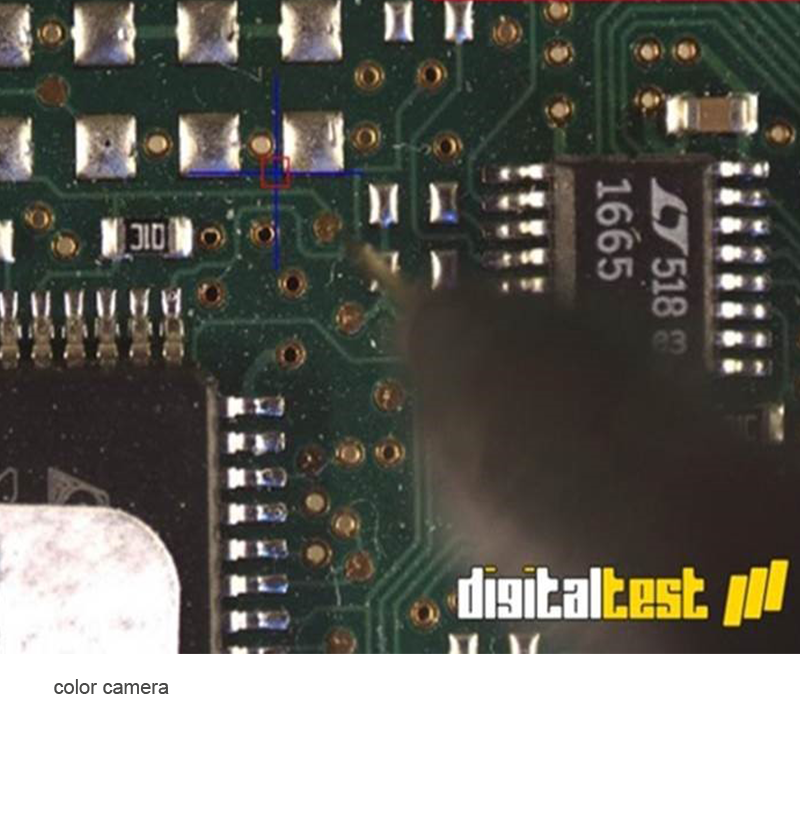

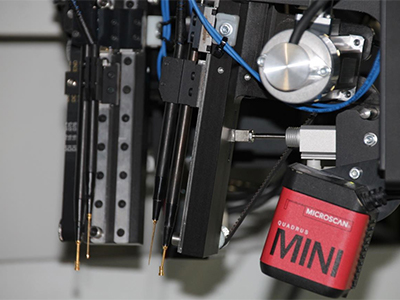

Color camera: The eye of the condor

The Condor Flying Probe is equipped with a digital color camera (CMOS) with GigE Vision interface to accurately determine the position of the probe and the DUT. It is attached to one of our four heads and contains both the optics and the lighting.

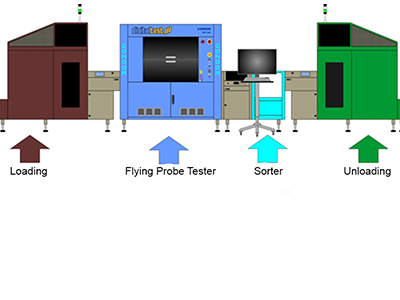

In-Line

Our in-line tester can be fully integrated into your production line. The circuit board moves automatically over the conveyor inside the tester via an in- and outfeed. The module is clamped up towards the top for testing, so that the PCB thickness makes no difference for contacting. SMEMA-compatible connections are available for pre-heat and post-cool modules in your production line.

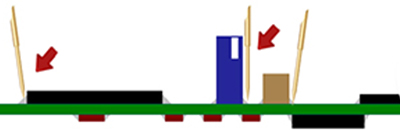

0-9 Degree Contacting

The test heads of our flying prober are attached to planar rotors and move on a testing axis – the so-called Z-axis. Software control allows the heads to meet the test point at a 0 or 9 degree angle.

If you approach a component at a 9° angle, this guarantees perfect contact and permits testing as close as possible to the component. With the 0°-setting you can ideally check test points between tall components or arched modules – thereby further increasing your test coverage.

Barcode Scanner

The barcode scanner located directly on the test head is controlled by the test program and assigns the test result to the correct test object.

The barcodes are easily recognised from any position.

Any scanner can be connected to the heads, single board barcodes as well as panels (barcode per board) are supported.

Soft-landing function

Circuit boards are getting ever smaller and more complex, especially in high-tech communication areas such as automotive, medicine and the military. This means the test points are also getting smaller and more sensitive to scratches from the test pins. These are the reasons we developed the “soft landing” technology for our Condor flying prober.

The principle is simple: the head travels at normal speed towards the test component, but brakes 1-2 mm before arrival. The pin then arrives gently, precisely and at reduced speed at the test point, without scratching the board and hardly leaving no markings behind.

With our soft landing function you can not only increase test coverage and testing accuracy, but also protect the board from scratches.

In-Circuit Test

Funktionstest

Boundary Scan FPT

With the boundary scan upgrade to our Flying Probe the needles can act as virtual JTAT/Boundary Scan cells. This increases fault coverage, since now the conductor paths that otherwise could not be reached can also be tested.

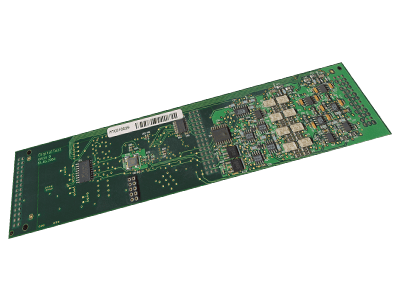

CAN-/LIN-Modules

The CAN-/LIN modules are standard interfaces for communication with the test object.

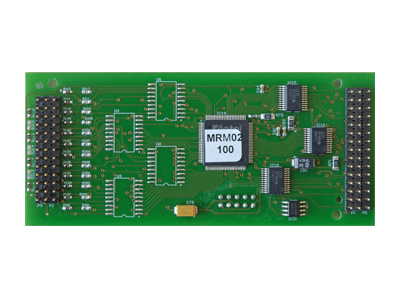

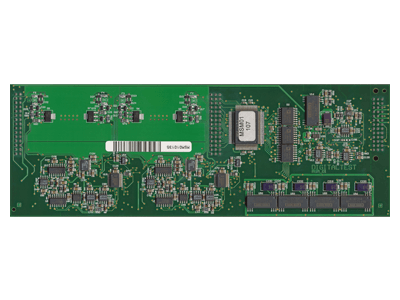

Programmer Modules

With the Programmer Modules you can make specific selections for onboard flash programming. Here we integrate for example programmers from Ertec, SMH, ProMik or Algocraft.

IEEE-, RS232-, USB-Modules

These functional modules have standardized PC interfaces for communicating with additional function test modules.

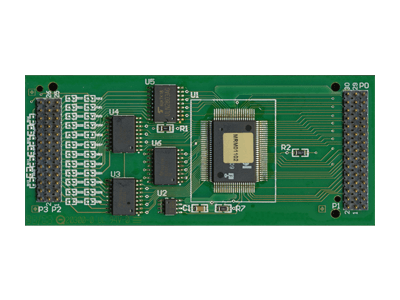

- Variant frontloader:

The interface consists of plug connectors (64-pin) – fixtures can be connected to them via cables. - Variant In-line:

The interface consists of plug connectors (64-pin) – fixtures can be connected directly to them.

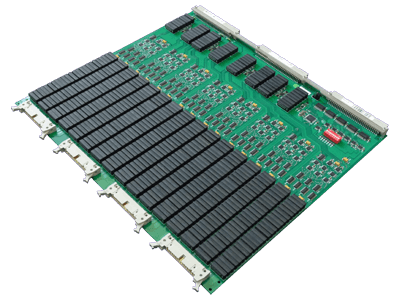

Multi-Level Fixture (incl. Condor Fixture Lifting Mechanism)

Two-stage device for the Condor Flying Prober with a lifting mechanism allowing the user to contact the same device in different ways.

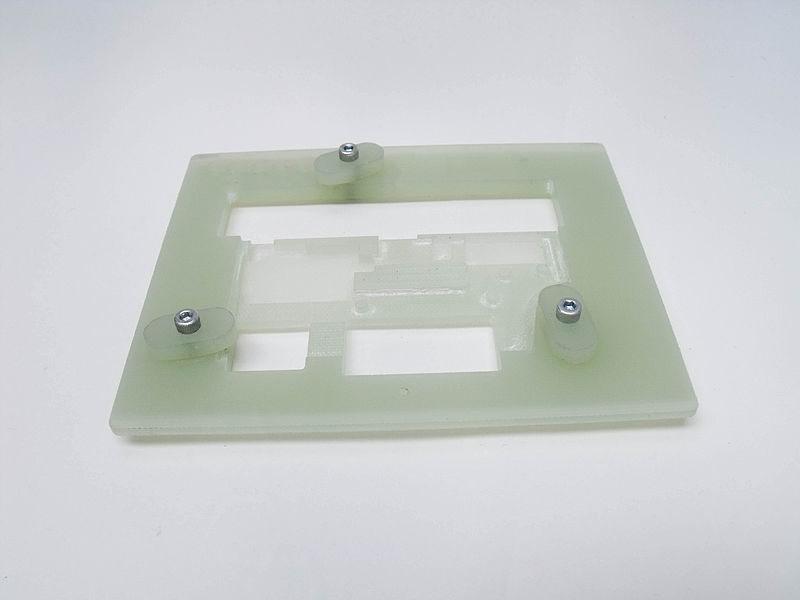

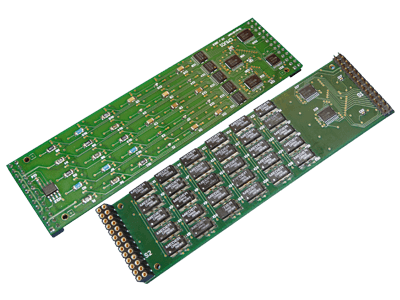

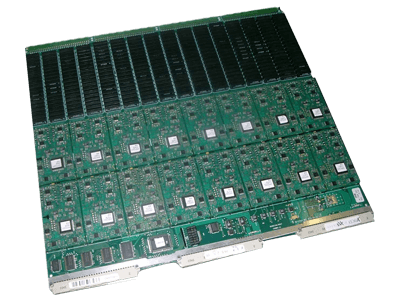

Flying Probe PCB Carriers

Customized PCB Carriers

Are you confronted with the challenge of not having to test inline-capable PCBs? Do your boards fall below the clamping edge of three millimeters? Digitaltest solves the problem and manufactures individually for you suitable PCB carriers, so-called trays. If the circuit boards are tested on one side in our frontloader, a clamping edge on two parallel sides as well as space for the variably adjustable clamping fingers on the other side of the board is sufficient. If these requirements are not met, our trays are a quick and easy solution.

Universal PCB Carrier

With this quickly deployable board handling system, your PCBs can be easily tested with our flying probe in front load as well as in in-line operation. Digitaltest has been using trays in its own production for a long time and has already manufactured such PCB carriers for many different types of electronic assemblies.

In order to avoid long waiting times for the construction of the fixtures, Digitaltest offers an in-house fixture service.