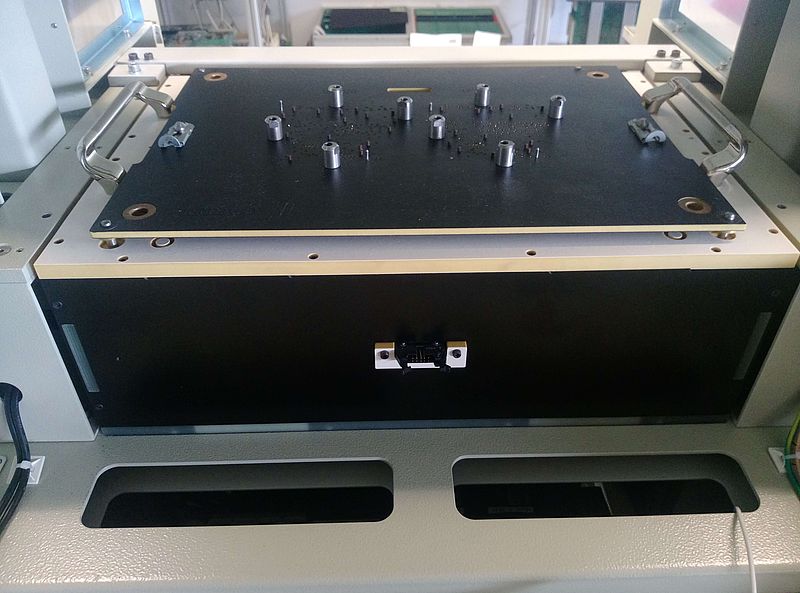

In-Circuit Test System with Pneumatic Press

The Eagle enables inexpensive testing with low-cost fixture solutions.

- Up to 3,456 pins at 5,500 N

- Economical fixture Solutions

- Pneumatic press

- One-Touch Fixture: Interface for fast exchange of fixtures

Downloads

- Product Flyer Eagle MTS 180 (A4 Format)

- Product Flyer Eagle MTS 180 (Lettersize Format)

- Test System Overview

- Test Strategy Flyer

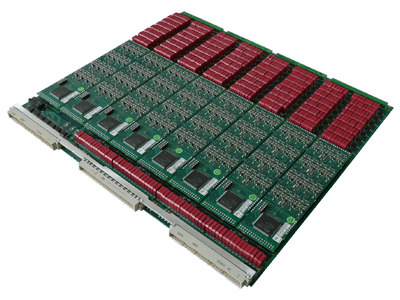

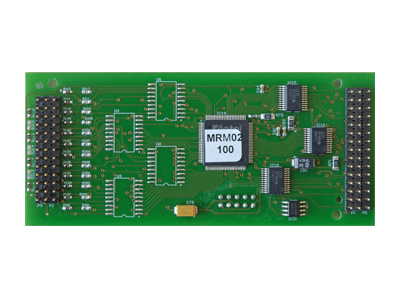

The Eagle MTS 180 is our most economical solution for high-volume production. The in-circuit tester is equipped with a press, so that you can dispense with expensive vacuum fixtures. The pneumatic press allows you to develop even highly complex fixtures at minimal cost.

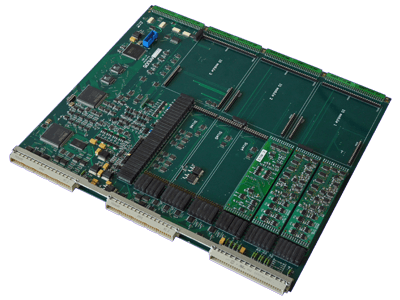

Our Eagle at 5500 N can be equipped with up to 3456 analog and hybrid in-circuit test pins, making it the ideal test system for EMS service providers and high-volume production. In addition, the test system can be equipped with functional modules for greater fault coverage or configured as a function tester.

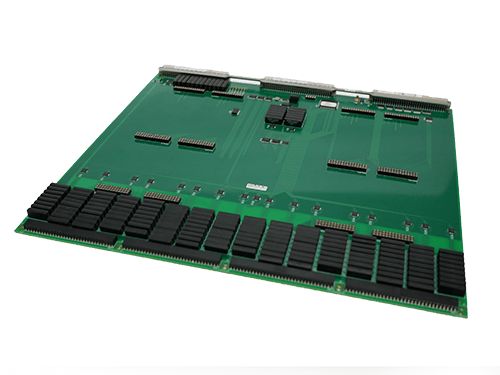

Quick-change interface (One Touch)

With our One Touch system you can change your fixtures quickly and simply using the clever quick-change interface.

Light curtain

A light curtain can be integrated in the system instead of a door the workstation for the pneumatic press can be protected using a light curtain, this enables the user to use only one hand, when opening or closing the press. Meanwhile the user can manually load and unload the systems with the other hand and this can save a great deal of time.

In-Circuit Test

Functional test

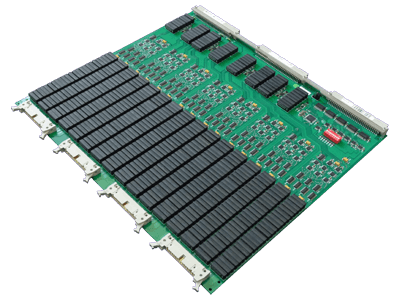

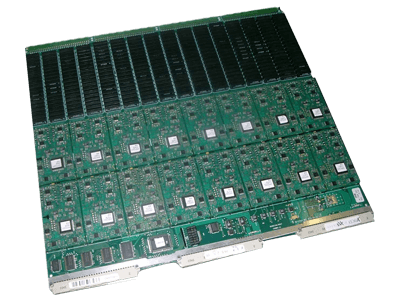

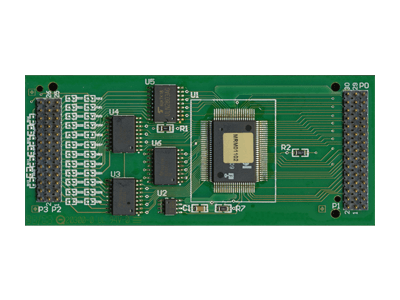

Lambda edition: real parallel testing as the solution

Would you like to test multiple boards in parallel and save time? We have the solution: real parallel testing with the Lambda edition. With this technology you can test two or more assemblies at the same time, thereby optimizing the cycle times and shortening the test time or performing the tests using the shortest path. An ICT or functional test is performed by two or more independent test heads, reducing the test time by the corresponding factor. This applies to multi-panels as well as for multiple independent single test objects.

The Lambda edition thus reduces the test time for two objects for example by 50 percent, or 75 percent for four, and so on.

Advantages of parallel testing

- Optimizes cycle times

- Small, economical test heads

- Powerful, flexible software environment

- Assemblies can be tested without additional effort

- Low hardware costs

- Takes up less space

Boundary Scan ICT

With our boundary scan upgrade for In-Circuit Tests (ICT) you can get the best of both testing methods worlds and achieve an optimal test strategy with maximum test coverage and reduced overall costs.

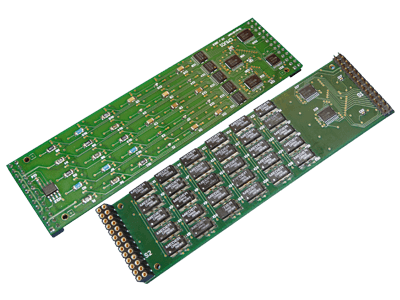

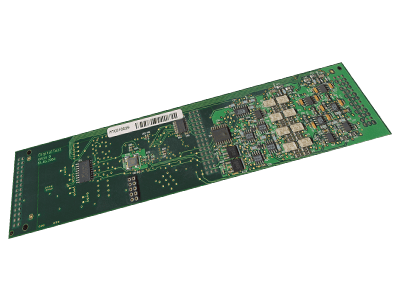

CAN-/LIN-Modules

The CAN-/LIN modules are standard interfaces for communication with the test object.

Programmer Modules

With the Programmer Modules you can make specific selections for onboard flash programming. Here we integrate for example programmers from Ertec, SMH, ProMik or Algocraft.

IEEE-, RS232-, USB-Modules

These functional modules have standardized PC interfaces for communicating with additional function test modules.

Ideal for

- Fixtures can make double-sided contact

- Fixtures can use rigid needles which are well suited for short distances and small pads

- Works with the compressed air fixture press

In order to avoid long waiting times for the construction of the fixtures, Digitaltest offers an in-house fixture service.