QMAN helps to repair faster as well as monitor and evaluate the production process

- Fast fault diagnostics and repair

- Enables conclusions to be drawn for improving performance and quality

- Visual inspection stations with checklists

- Process monitoring with automatic serial fault detection

- Intelligent repair database

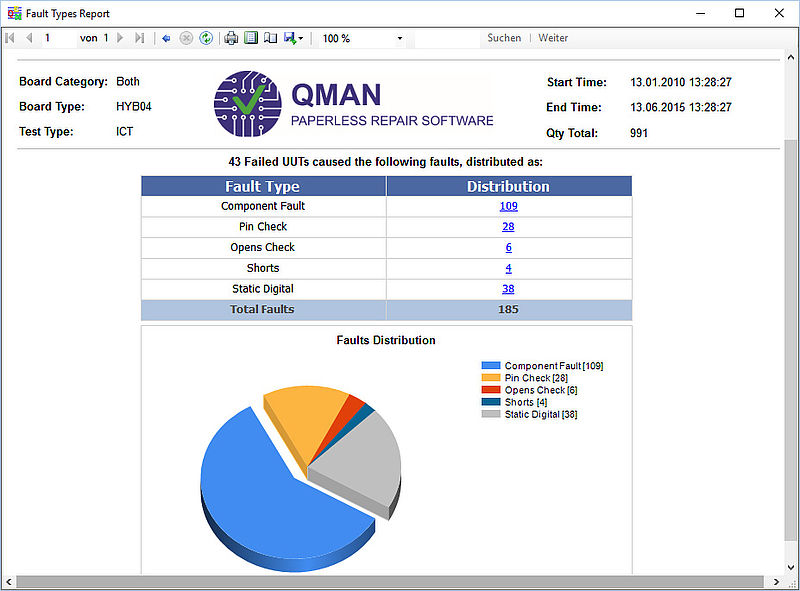

- Comprehensive statistical reports

- Drill-down functions

Paperless Repair

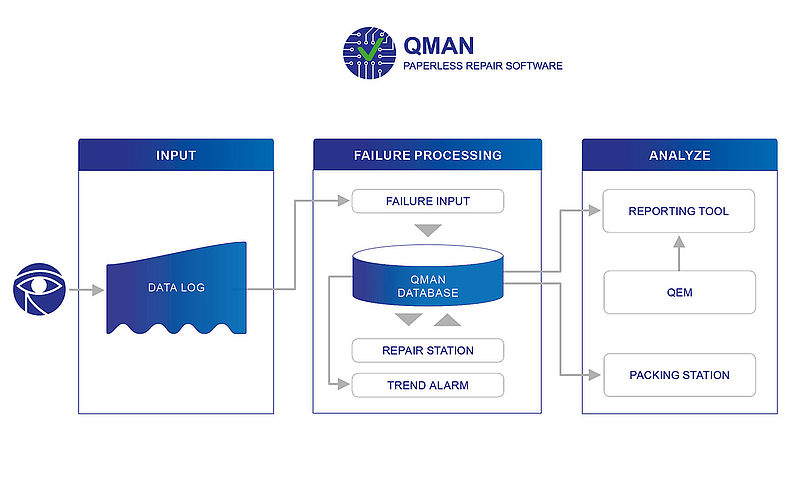

The Paperless Repair software QMAN is a powerful quality management system. It helps achieve higher quality assurance, reduce production costs and shorten repair time – regardless of which test system you are using.

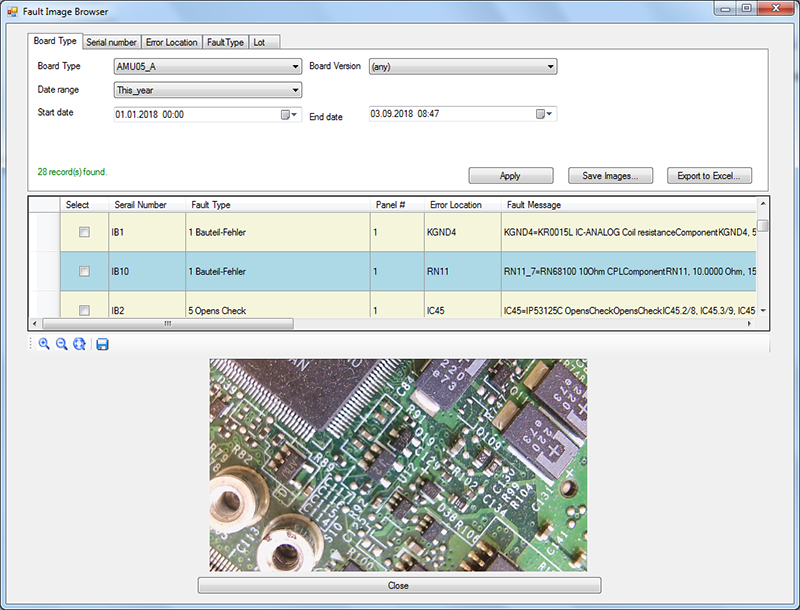

Fault Image Browser

With the Fault Image Browser, you can take photos using a camera connected to your PC, assign them to an fault, save them and analyse them using an Excel export.

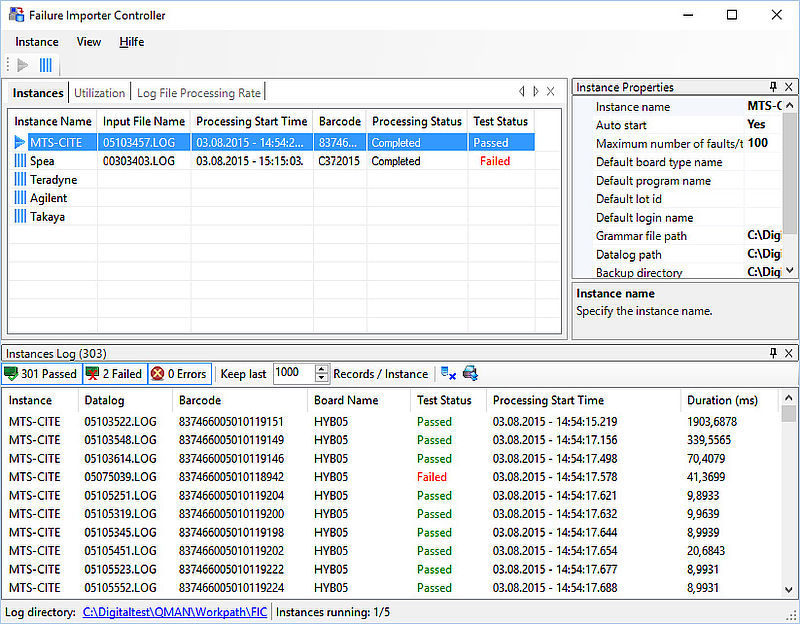

Failure Import

- Interface to test and inspection systems.

- With the additional debug tool new interfaces can be created and customized.

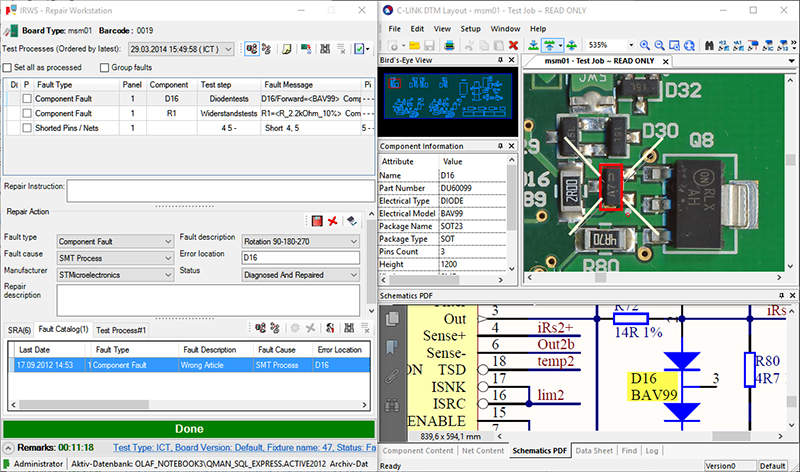

Repair Station

To optimize repair time, paperless repair has an integrated failure catalog, schematics and layout viewer.

Visual Inspection Station

Each PCB type can get one or more checklists for visual inspections assigned. The checklists are stored one central place in the database.

Functional Test Station

All test systems, which do not have a data log functionality can be connected to QMAN.

CORS - Complete Optical Repair Solution

With the Complete Optical Repair Solution (CORS) from Digitaltest manual search and identification of errors on assemblies will no longer be necessary in the future, which can save time and money.

Digitaltest has developed with CORS, the Complete Optical Repair Solution, a special procedure, with which the troubleshooting is no longer as before manual, but via a fully automated camera system. The IP-3000 optical inspection system is centrally controlled via the QMAN Repair Stations software remote controlled and shows the fault location as a live image on a high-resolution monitor.