Description

Features

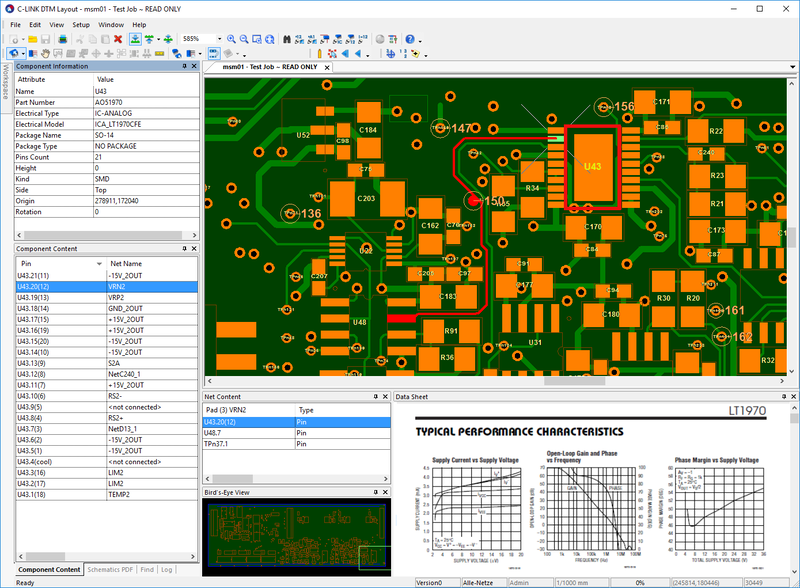

- Display of components, nets, pads, test points, drill holes, fixture information

- Measuring tool for test pad distances

- Marks potential short-circuit locations

- Photo of the PCB as an additional graphical layer

- Component parts list information

- Communication to PDF schematics

- Bi-directional communication to schematics viewer

- Extensive search functions with intuitive shortcuts

- Can be remotely controlled by third-party software

- Changes that are made universally and are available at all production steps

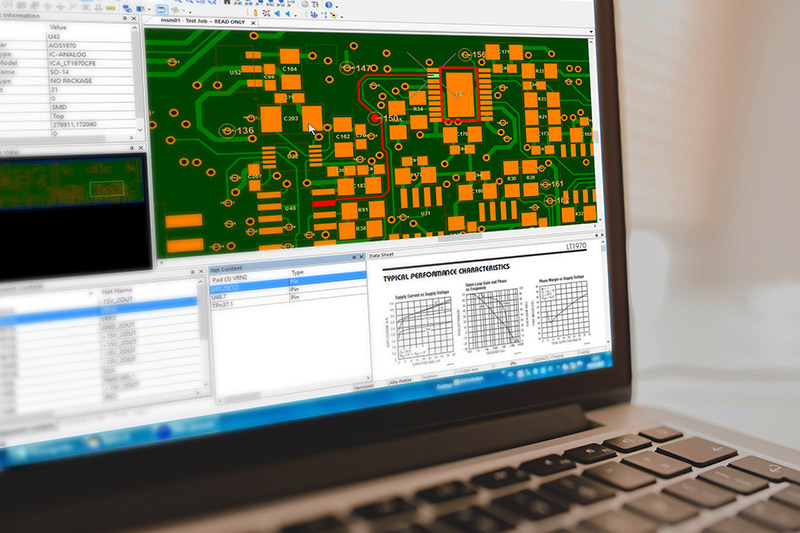

The CAD Viewer layout software displays converted CAD data from printed circuit boards and is used for test program creation, PCB repair, manual assembly and also for fixture maintenance.

The CAD viewer layout software from Digitaltest is perfectly tailored to the requirements of electronic manufacturing and can be used in many different stages of the production. The software is designed to be intuitively, so that anyone can learn quickly the extensive functions. The CAD Viewer layout software from Digitaltest helps you to produce your PCBs fast and safely.

Test engineers benefit from the layout information when creating in-circuit and function test programs. In addition to comprehensive information on components and network list, contactability is also available. Communication to the circuit diagram completes the range of functions and enables test programs to be created more quickly. In addition, Condor Flying Probe users can change the contact settings and define engineering change orders (ECOs).

Users at analysis and repair stations can quickly identify fault locations on the module. With the help of the extensive search functions, short circuits or faulty components are located immediately. All details of the assembly including the operating instructions are available visible for the manual assembly.

Service personnel can simply maintain fixtures by using the layout viewer to retrieve all information needed, including the probe locations and the type of spring loaded probes, channel numbers and also tooling pins. This helps to significantly reduce servicing time which results in an increase of availability of the test equipment, without long periods of production stop.

The CAD Viewer layout software can be operated with any programming station or standalone. The COM interface enables communication with third-party software, e.g. In-house paperless repair or traceability.

Description

Features

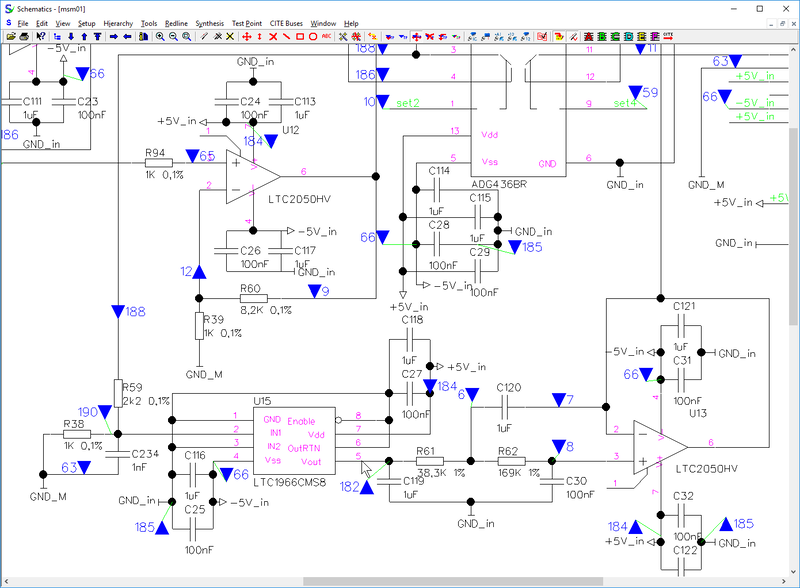

- Search for components, component pins, nets and channel numbers

- Text and drawings can be added for debugging and repair

- Import fixture information and display the channel numbers of the test pins

- Import of so-called message files for the visualization of test coverage, test methods, highlighted non-contactable networks, and more.

- Synthesis for the representation of all components connected to a network; Overview of all network participants

- Cross-Probing for bidirectional communication with Layout-Viewer

- BOM information from the schematics data is extracted

- Interactive debugging of the test program on MTS test systems

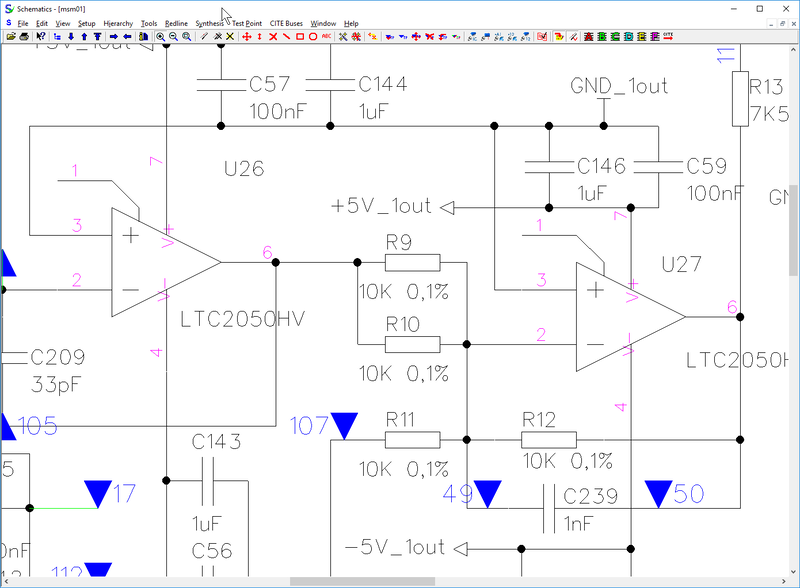

The CAD Viewer Schematics software displays converted CAD data from PCBs and is used for test program creation, PCB repair and quality assurance.

Have you ever worked with PDF schematics diagrams or even schematics diagrams in paper form? Then you must know how tedious this is. The CAD Viewer Schematics software is easy to use, and it also has far more features than PDF schematics.

The CAD Viewer Schematics Viewer software helps tremendously to create a test program because the schematics are completely searchable. When using an MTS system, it is even possible to change the test parameters at any time, and this speeds up the process and facilitate the debugging of a test program considerably. The test coverage, can also be verified again.

Faults, which are difficult to locate, such as faults found by function tests, can be easily determined and repaired quickly. For the repair station, even instructions can be provided in the form of text or drawings.

Quality assurance can instantly understand what is being tested and what is not tested and can take immediate action, such as a redesign or additional test methods.