Automated Repair Of Printed Circuit Boards With CORS

Process optimization in manual visual inspection

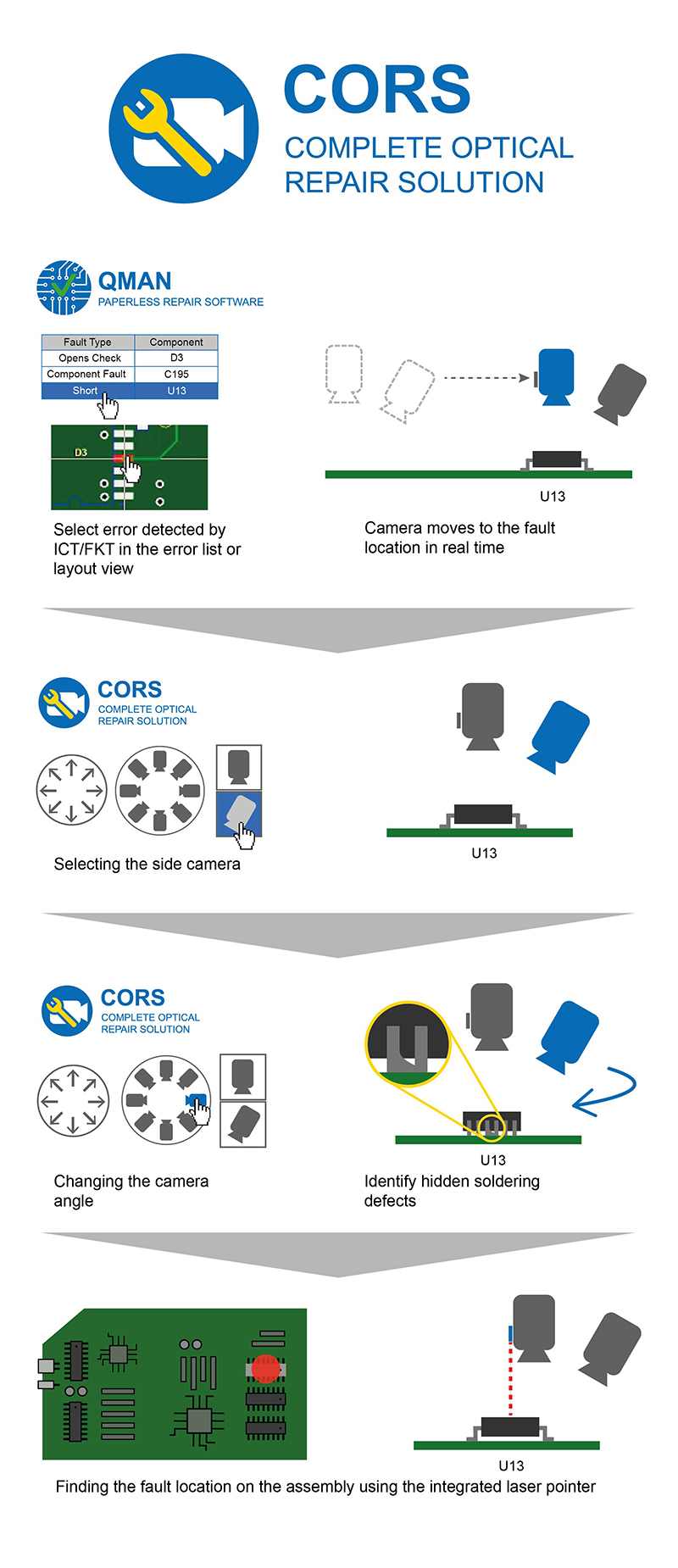

Manual Visual Inspection (MVI) is an optical test procedure in which the assembly is manually inspected with a magnifying glass for detectable defects. The quality of the inspection depends on the concentration and qualification of the respective employee and therefore fluctuates greatly. This procedure was and is very time-consuming, especially with advancing miniaturization and high packing density, which means that high costs are also incurred for large quantities. With CORS, the Complete Optical Repair Solution, Digitaltest has developed a special procedure with which troubleshooting is no longer carried out manually as before, but via a fully automated camera system. The IP-3000 optical inspection system is remote-controlled centrally via the QMAN Repair Stations Software and displays the location of the defect as a live image on a high-resolution monitor. QMAN imports the test results from various test processes, which in turn enables faster analysis. In the event of an error, the defective assembly can then be repaired in the shortest possible time with the help of QMAN. The solution is in the detail, in the case of CORS in the camera system of the IP-3000 inspection system: the side cameras installed there enable both solder joint inspection and faster detection of short circuits.

With the help of the QMAN Fault Image Browser, pictures of faults as well as repaired faults can be saved in the QMAN database. These pictures are used for detailed documentation and are decisive for later analysis.

Advantages

- Simple error localization of assemblies

- Live image for faster analysis and repair

- Cost savings through less waste

- Environmental protection through repair instead of disposal