Lexicon

Panel Separators

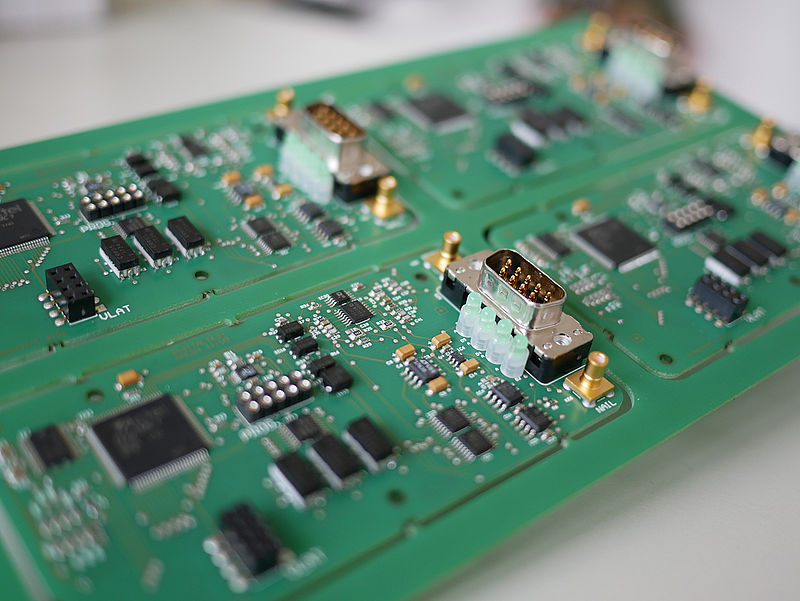

Devices for separating PCBs are referred to as panel separators. The factors used to select a depaneling machine are the PCB design (shape, contour, structure etc.), the specified accuracy, the permissible mechanical stress, cycle time, quality specifications and costs.

In order to isolate the boards from the panel after assembly, appropriate separation processes must be applied depending on the type of connection (scribing panel, milling panel). The most frequently used techniques are roller knives, punching devices, wedge knives or milling devices. During the cutting process, the PCBs and the assembled components must be subjected to little mechanical stress. Therefore, the layout of the printed circuit boards should take the later panel design and the possible processes for panel separation into acount.