Lexicon

Panel

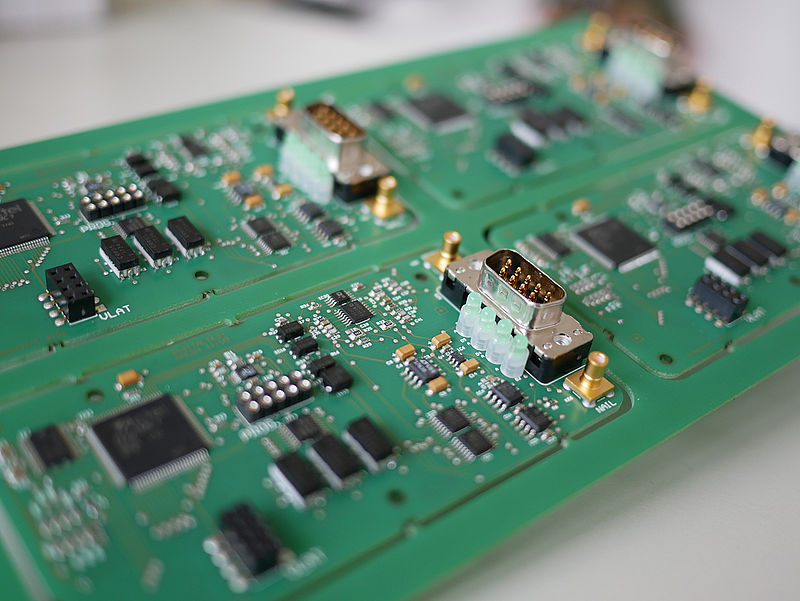

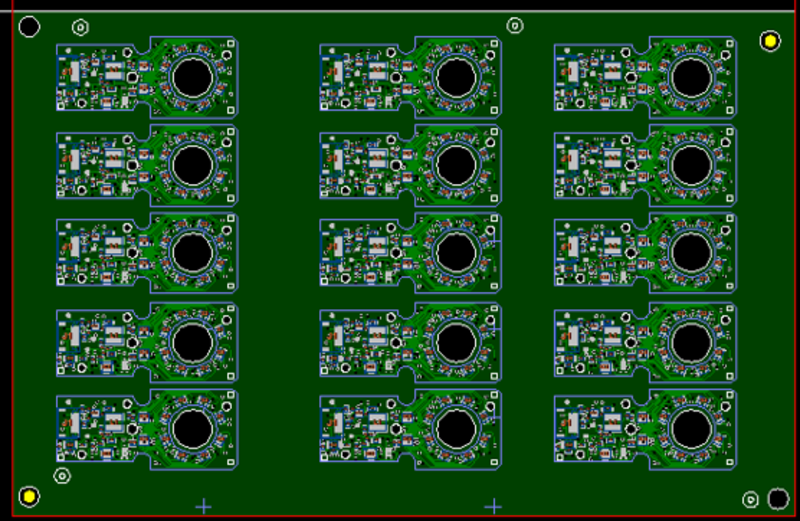

In the electronics industry, a panel is a composite of several individual PCBs and is assembled and may be tested in the same way. The benefit is that it can include several identical, yet different individual boards (mixed panels) and must be separated in the course of production. Various techniques and so-called panel separators are used to separate the overall panel, e.g. cutting, breaking, laser cutting, sawing or punching.

Often a panel makes it possible to assemble a single board. Another major cost advantage is that approx. 70 to 80 percent of PCB manufacturing costs are fixed costs, regardless of the number of PCBs per panel. Another reason for producing in panels is the higher throughput rate of the systems, since only one individual transport and handling process is required per panel. This significantly increases the cost-effectiveness of automated production for printed circuit boards and electronic boards. This also applies to the user test or panel test.

A disadvantage of the production of useful components is the fact that the components can be damaged if they are separated later. A single defective circuit board which cannot be repaired economically often eliminates the overall benefit.