News

News Press Software Test Systems

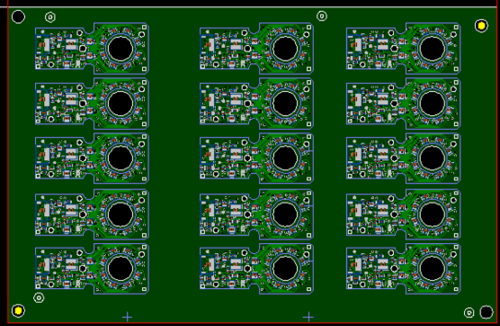

Successfully PCB panel testing

Today, panelization has become the new standard in production assemblies, because multiple panels save time and money. What about the in-circuit test or functional test of the finished circuit boards? Many electronics manufacturers still hesitate when it comes to panel testing. The advantages are obvious: even miniature PCBs can be tested, the PCB is twist-proof thanks to its dual use, and higher quantities can be tested in a shorter time with less use of resources. So why do the majority separate the panel into single boards before the in-circuit test?

Press release: